I needed 48 tweeters to make a 65″ line array, so I came up with a very simple design that I can make quickly. This design uses readily available materials, and it is not overly difficult to construct.

I used the small (1″ square) air motion transformer (AMT) diaphragms available at Aliexpress, which are sold in pairs. These appear to be the same diaphragm as used in the Dayton Audio AMT Mini-8 and sold under many other brand names. The diaphragms are packaged in a round thermoplastic frame, which I trim on a disk sander to about 1-1/8″ square.

The magnet structure uses a “magnet sandwich” with .106″ perforated steel sheet to conduct the magnetic flux. Cutting the perforated steel sheet proved to be the hardest part of this project, but I found that using a 5-3/8″ metal cutting blade in a Ryobi floor saw made the task go quickly and it wasn’t too messy. I had purchased the floor saw as a refurbished unit for about $100 to put up tongue and groove siding, and it worked well for that job, also. The steel cutting blade is made by Diablo and it sells for around $40.

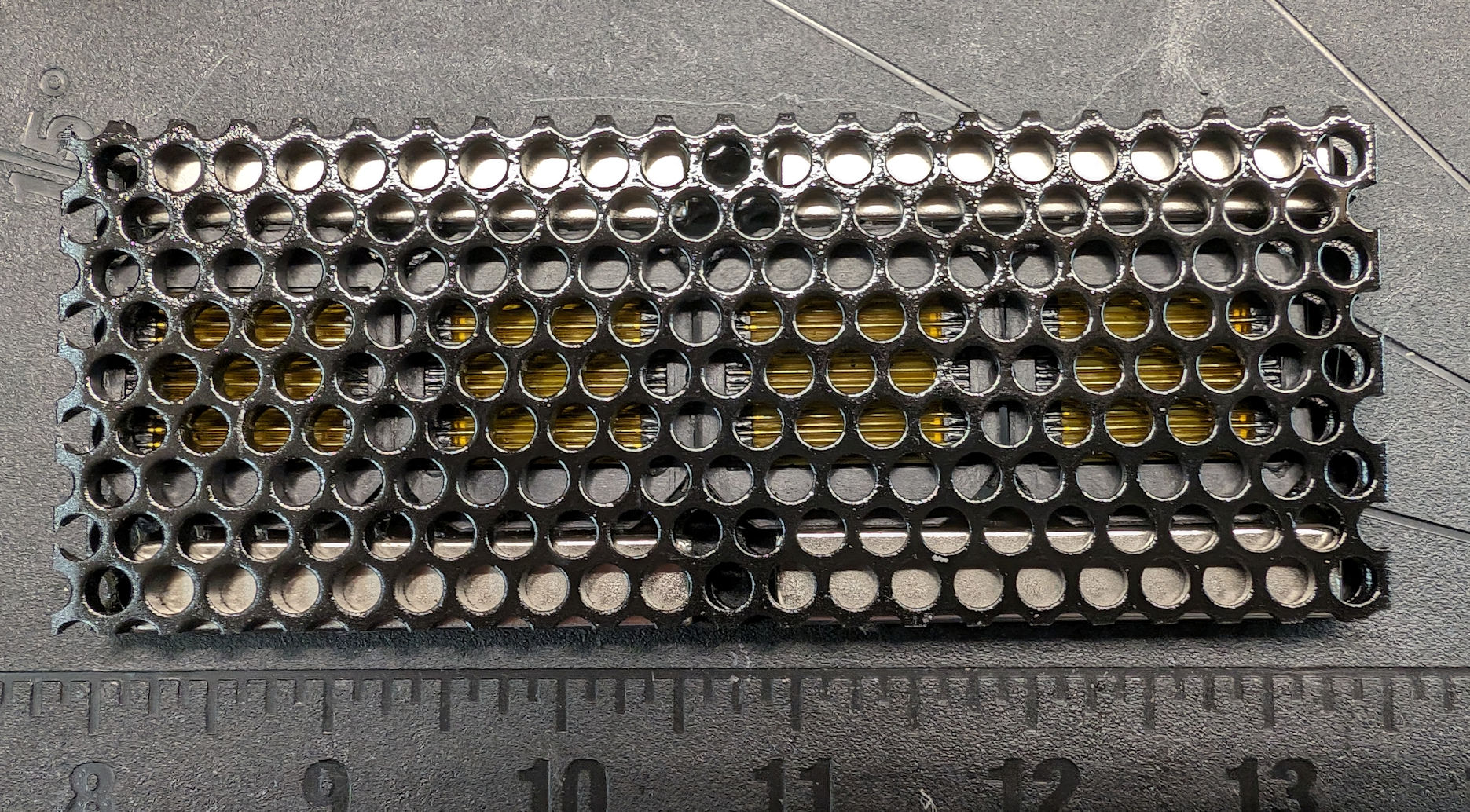

To keep the cutting to a reasonable amount, I decided to make the tweeters in groups of 4. That made each tweeter a “quad” that was about 5-1/4″ long. The width was 2-1/8″, which allowed room for the diaphragm and the magnets. The perforated steel is available in 12″ squares at Online Metals, and it takes 5 sheets to make 24 quad tweeters. It is about 50% open, which makes it ideal for these AMT tweeters. The .106″ thickness provides a study structure and results in a strong magnetic field.

The magnets are readily available 3mm x 10mm x 60mm magnets that Amazon sells for about $0.60 apiece in packs of 25. Since the AMT diaphragms are about 2.7mm thick, the 3mm magnets are a perfect thickness.

You can see the 4 diaphragms and the 4 magnets before the top grill is installed:

Obviously, you need to make sure that all of the magnets are oriented with the same polarity. I used 5-minute epoxy to secure the magnets, using a block of wood in between the two rows to keep the magnets from sliding around until the epoxy set. You need to be very careful during final assembly, as the magnets will try to pinch any fingers that get in the way. Here is what the completed tweeter looks like from the front:

The back looks similar, except there are 8 wires sticking out for the 4 tweeters. So, yes, this is a dipole tweeter, although you can enclose the back with a small chamber if you do not want the dipole radiation.

Another nice feature of this design is that grinding down the diaphragm edges and just putting magnets on the vertical sides helps minimize the comb filtering effect that sometimes affects line array tweeters. The distance between individual tweeter membranes is less than 1/2″ and the distance between groups of tweeters will be less than 3/4″. As a result, the vertical response should be consistent all the way up to 10,000Hz or so.

I’ve only completed one tweeter so far, but it looks like this design will work just fine. Unfortunately, it doesn’t look like you can cut all of the perforated sheet using just one metal cutting blade, as the blades suffered a lot of damage after I had finished cutting about one half of the pole pieces. Check out the chipped or missing teeth:

I’ve still got lots of testing to do once the tweeters are mounted on the line array front panel, and those results will show up in a later blog.

Leave a Reply